How (& When) to Comply with New OSHA Chemical Safety Requirements

Over the next eight months, OSHA will be completing the phasein of the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), its most important new chemical safety rules in over a decade. Here’s an overview of GHS, what clinical and anatomical laboratories must do and by when. What’s At Stake If preventing chemical injuries and illnesses to lab workers is not motivation enough, complying with the new GHS rules is crucial to head off OSHA complaints, inspections, fines and other penalties. And don’t forget about the negative publicity that comes with being charged with OSHA violations. Failure to comply with GHS can also put your Medicare status in jeopardy. Explanation: In completing its 855b Medicare Enrollment Application, your lab must certify that it meets all applicable federal and state requirements, including OSHA. In addition to costing you your right to participate in Medicare, GHS violations can turn your certification of compliance into a false representation exposing your lab to liability (and the risk of triple damages) under the federal False Claims Act. What GHS Is All About Like other industrialized countries, the U.S. has adopted safety rules requiring employers to ensure their workers’ "right to know" about the […]

Over the next eight months, OSHA will be completing the phasein of the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), its most important new chemical safety rules in over a decade. Here's an overview of GHS, what clinical and anatomical laboratories must do and by when.

What's At Stake

If preventing chemical injuries and illnesses to lab workers is not motivation enough, complying with the new GHS rules is crucial to head off OSHA complaints, inspections, fines and other penalties. And don't forget about the negative publicity that comes with being charged with OSHA violations.

Failure to comply with GHS can also put your Medicare status in jeopardy. Explanation: In completing its 855b Medicare Enrollment Application, your lab must certify that it meets all applicable federal and state requirements, including OSHA. In addition to costing you your right to participate in Medicare, GHS violations can turn your certification of compliance into a false representation exposing your lab to liability (and the risk of triple damages) under the federal False Claims Act.

What GHS Is All About

Like other industrialized countries, the U.S. has adopted safety rules requiring employers to ensure their workers' "right to know" about the hazardous chemicals used, handled or stored in the workplace. Those rules are set out in the OSHA Hazard Communication standard (Hazcom). Because different countries follow different rules, the U.N. developed an international system called GHS to standardize workplace chemical safety rules around the world. OSHA adopted the GHS in May 2012 to bring Hazcom and U.S. rules into line with the UN system.

How GHS Affects Labs

GHS is not actually a new rule but a set of revisions to existing Hazcom rules. As those of you familiar with OSHA lab requirements may already know, chemical safety in clinical and anatomical labs is governed not by Hazcom but a separate, less rigorous regulation called the Occupational Exposure to Hazardous Chemicals in Laboratories standard (Sec. 1910.1450)) (Labs Standard). That means GHS has nothing to do with labs. Right? Wrong! Hazcom and GHS do affect labs, either directly or indirectly. Many labs subject to the Labs Standard are actually subject to Hazcom too. The chemical safety standard that applies, in other words, is determined not simply by the location being a lab but by the type of operation carried out there:

- Laboratory operations are subject to the Labs Standard: Such operations include handling and uses meeting all of the following four conditions: i. Chemical manipulations are carried out on a "laboratory scale," i.e., work with substances in which containers are designed for easy handling by one person; ii. Multiple chemicals are used; iii. The procedures aren't part of a manufacturing production process; and, iv. "Protective laboratory practices and equipment" are available to minimize risk of worker exposure.

- Non-laboratory operations are subject to Hazcom: Such operations include any other use of a hazardous chemical not defined above as a laboratory use, including use of chemicals for building maintenance, production of chemicals for commercial sale and quality control testing.

Result: A facility in which lab and non-laboratory operations are carried out would need two separate chemical safety systems—a Labs Standard system to protect workers performing the laboratory operations and a Hazcom system to protect workers who perform non-laboratory operations, such as custodians performing lab maintenance. Rather than going to the trouble of establishing and coordinating parallel systems, many labs use a single system for all workers and operations that is tailored to the requirements of Hazcom, since it is the more stringent of the two standards. Even labs that are subject to just the Labs Standard are indirectly affected by Hazcom. Explanation: GHS makes changes to the chemical labels and Material Safety Data Sheets, now simply referred to as Safety Data Sheets under the GHS (MSDSs/SDSs) required under Hazcom. And labs subject to the Labs Standard are also required to use these instruments.

The 3 Things You Must Do to Comply with GHS

Assuming that your lab is a downstream user, rather than a manufacturer, importer or distributor of hazardous products regulated by Hazcom, there are three things you need to do to comply with GHS:

1. Provide GHS Training. Deadline: Dec. 1, 2013 & Ongoing Labs must ensure that all workers exposed to hazardous chemicals receive proper GHS safety information and training. You should already be providing chemical safety training to exposed workers. GHS simply requires that your training account for the GHS changes, including at a minimum:

- Methods to detect and guard against chemical releases;

- Physical hazards posed by different chemicals;

- Health hazards posed by those chemicals;

- How to read the new GHS labels (see the section below); and

- How to access and read the new SDSs (see third section below).

What to Do: The deadline to provide initial GHS training was Dec. 1, 2013. Going forward, you must provide GHS training to workers on a continuing basis including initial training for new workers and current workers who are not currently exposed to hazardous chemicals when they are assigned to new jobs that involve exposure to hazardous substances (or whenever new chemical hazards for which they have not already been trained are introduced to their work areas). GHS training must be delivered to workers before they begin the job that involves exposure.

2. Replace Hazcom with GHS Labels. Deadline: June 1, 2016 As before, all containers of hazardous chemicals used, handled or stored in your lab must be marked with a label displaying important safety information about the product. But while the label requirement is not changing, the label itself is:

| Current Hazcom Label Elements | GHS Label Elements |

| • Identity of chemical | • Product identifier |

| • Hazard warnings | • Signal word |

| • Name and address of manufacturer, importer or other responsible party | • Hazard statement(s) |

| • Pictogram(s) | |

| • Precautionary statement(s) | |

| • Name, address phone number of manufacturer, importer or other responsible party |

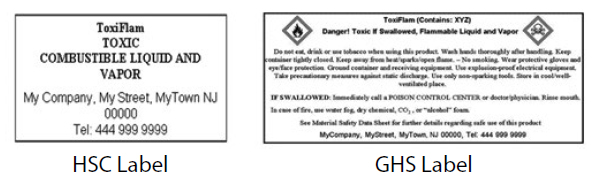

GHS labels will also have a new format and even a third color—red. Here's a sideby- side comparison with labelling examples OSHA uses for a fictitious product. The diamond shaped borders on the pictograms need to be in red:

What to Do: Although you have the option of creating it yourself, you can get a label for a particular chemical from the manufacturer or distributor that supplies the product to you. Between now and June 1, 2016, chemical labels can meet either current Hazcom or GHS requirements. After that date, only GHS labels will do.

3. Replace MSDSs with SDSs. Deadline: June 1, 2016. Under current rules, all hazardous chemicals in your lab must have what's called a Material Safety Data Sheet, or MSDS, that describes the product, the hazards it poses and the safety precautions for using it. You must also keep and ensure workers have access to a binder containing up-to-date versions of each MSDS. The MSDS and MSDS binder will continue to be key elements of your lab safety program. But under GHS, the MSDS is morphing into the SDS—short for Safety Data Sheet. And it is not just the name. The new SDS has a different format and lists different information from the MSDS.

| Current Hazcom MSDS Elements | GHS SDS Elements |

| • Identity of hazardous chemical | • Chemical identification |

| • Physical & chemical characteristics | • Hazard identification |

| • Physical hazards | • Information about chemical composition or ingredients |

| • Primary route(s) of entry | • First-aid measures |

| • Exposure limit, e.g., PEL, TLV | • Fire-fighting measures |

| • Whether chemical is listed in National Toxicology Program Annual Carcinogens Report | • Accidental release measures |

| • General precautions for handling & use | • Handling & storage information |

| • General control measures | • Exposure controls & personal protection |

| • Emergency & first aid procedures | • Physical & chemical properties |

| • Date of preparation or latest change | • Stability & reactivity |

| • Name, address & phone number of manufacturer, importer, employer or other responsible party that prepared or distributed MSDS | • Toxicological information |

| • Ecological information | |

| • Disposal considerations | |

| • Transport information | |

| • Regulatory information | |

| • Other information including date of preparation or latest change |

What To Do: As with the MSDS, the chemical's manufacturer or importer is responsible for preparing the SDS, although you can prepare your own SDS if you prefer. Between now and June 1, 2016, your MSDS binder must contain up-to-date versions of either an MSDS or SDS for each hazardous chemical. After that date, hazardous chemicals must have an SDS and only an SDS.

Takeaway: Laboratories must make sure chemical labels and safety data sheets are up-to-date before next June.

Subscribe to view Essential

Start a Free Trial for immediate access to this article